Photo from wikipedia

Abstract As having high heat resistance, excellent mechanical and tribological properties, Polyether-Ether-Ketone (PEEK) is widely used in aerospace, rail transit, etc. The short basalt fiber (BF) reinforced PEEK composites were… Click to show full abstract

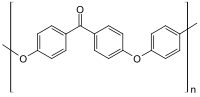

Abstract As having high heat resistance, excellent mechanical and tribological properties, Polyether-Ether-Ketone (PEEK) is widely used in aerospace, rail transit, etc. The short basalt fiber (BF) reinforced PEEK composites were fabricated to further improve the mechanical and tribological properties. With increasing BF content, the surface roughness of composites increases, while the friction coefficient decreases gradually, attributing to a certain lubricating friction film formed on the part surface. With a BF content of 25 wt%, the specific wear rate of the composites reaches the lowest value of 5.28 × 10 −7m3 /N·m, which is an order of magnitude lower than that of neat PEEK. Simultaneously, good ultimate tensile strength and the elongation at break were achieved, reaching 150 MPa and 31% respectively. Thermal and rheological behaviors of the composites were also investigated through differential scanning calorimetric (DSC) and rotating rheological testing to understand the effect of BF on the crystallization performance and flow abilities of PEEK composites.

Journal Title: Composite Structures

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!