Photo from wikipedia

The oxidation behaviour of IN 718 alloys produced by laser beam melting and electron beam melting was compared to that of the wrought alloy at 850 °C in laboratory air. Oxide… Click to show full abstract

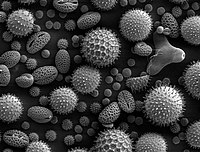

The oxidation behaviour of IN 718 alloys produced by laser beam melting and electron beam melting was compared to that of the wrought alloy at 850 °C in laboratory air. Oxide scales of all alloys were similar in nature and morphology with small differences due to powder particles sintered on the surface of additive manufacturing parts. Nevertheless, major differences in surface topography were noticed, these could affect surface area estimations and consequentlymass gain estimations. A quantitative correlation was determined between apparent parabolic rate constant and surface area.

Journal Title: Corrosion Science

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!