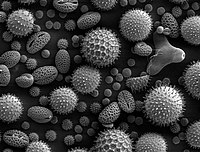

Photo from wikipedia

Abstract The oxidation of 316 L stainless steel in hydrogenated supercritical water at 600 °C is strongly dependent on the effects of work hardening induced by surface finishes. The oxide scale formed… Click to show full abstract

Abstract The oxidation of 316 L stainless steel in hydrogenated supercritical water at 600 °C is strongly dependent on the effects of work hardening induced by surface finishes. The oxide scale formed under these conditions is always double-layered with an external layer of Fe-rich oxides. However, when a hardening threshold is reached, a switch in oxidation mechanisms leads to a considerable thinning of the oxide scale. This thinning results from the formation of a Cr-rich internal oxide layer that acts as a diffusion barrier against ionic species responsible for its growth but also against Fe cations implied in the external layer growth.

Journal Title: Corrosion Science

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!