Photo from wikipedia

Abstract To solve the problem of uniform high-quality sintering of large-diameter polycrystalline diamond compact (PDC) cutting tool material on a cubic press, the design of a high-temperature, high-pressure (HTHP) sintering… Click to show full abstract

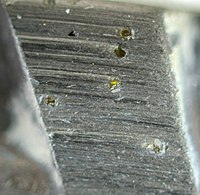

Abstract To solve the problem of uniform high-quality sintering of large-diameter polycrystalline diamond compact (PDC) cutting tool material on a cubic press, the design of a high-temperature, high-pressure (HTHP) sintering cavity assembly structure of a cubic press is optimised. PDC cutting tool materials with Φ62 mm were successfully sintered at a pressure of 5.5–5.8 GPa and a temperature of 1550–1650 °C. The microstructure and phase composition of PDC samples were detected by scanning electron microscopy, X-ray diffraction, and Raman spectroscopy. The microhardness, flexural strength, interfacial shear strength, wear resistance, and heat resistance of the samples were tested by a Vickers hardness tester, universal testing machine, and an abrasion ratio tester, and their uniformity was analysed. The test results show that the microhardness of Φ62 mm PDC is 86.25 GPa, which is 13.34% higher than that of the conventional PDC cutting tool material on the market; the bending strength is 1398.6 MPa; the interfacial shear strength is 2690.4 MPa; and the wear ratio is 29.8 × 104 with only an 8.09% decrease from the peripheral point to the central point. The wear resistance is basically uniform in the radial direction, indicating that the HTHP sintering process and the structure of the sintering cell assembly are reasonable, and the temperature and pressure field distributions inside the high-pressure sintering cavity are uniform, thereby realising uniform, dense sintering of the Φ62 mm PDC. When the PDC sample was calcined at 750 °C for 2 min, the wear resistance was 29.8 × 104, which is 10.59% lower than the wear resistance at room temperature, and the sample had good heat resistance.

Journal Title: Diamond and Related Materials

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!