Photo from wikipedia

Abstract Utility boilers are used in thermal power plants. If exhaust flue gas temperature of a boiler is sufficiently high, heat recovery devices may be installed to increase the boiler… Click to show full abstract

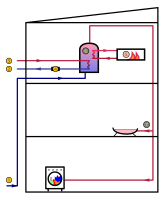

Abstract Utility boilers are used in thermal power plants. If exhaust flue gas temperature of a boiler is sufficiently high, heat recovery devices may be installed to increase the boiler efficiency. Previous investigations have focused on increasing boiler efficiency by using heat transfer from flue gas to remove moisture from fuel in flue gas dryer. Another method that is equally effective in increasing boiler efficiency is installing additional air heater to increase air temperature before combustion. The main objective of this paper is to determine the optimum sizes of flue gas dryer and additional air heater that minimize the total cost of installing them in an existing boiler. Models of utility boiler and flue gas are developed for this purpose. It is found that the installation of flue gas dryer after additional air heater results in lower total installation cost than the installation of flue gas dryer before additional air heater or the installation of flue gas dryer in parallel with additional air heater. Furthermore, both flue gas dryer and additional air heater should be installed if the ratio of the unit cost of flue gas dryer to the unit cost of air heater is between the lower and upper limits.

Journal Title: Energy

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!