Photo from wikipedia

A novel low pH fermentation process was studied for the conversion of lactose using Lactobacillus plantarum and Lactobacillus buchneri under anoxic conditions in single co-culture, and two-stage sequential fermentations. This… Click to show full abstract

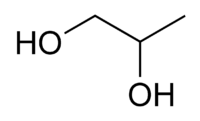

A novel low pH fermentation process was studied for the conversion of lactose using Lactobacillus plantarum and Lactobacillus buchneri under anoxic conditions in single co-culture, and two-stage sequential fermentations. This is aimed at producing acetate and propylene glycol (PG) as environmentally benign substitutes for currently used road and aircraft deicing chemicals. The results indicate that in the case of two-stage fermentation with immobilized L. buchneri in the second stage, lactose degradation rate increased markedly producing acetate and PG concentrations of 12.1 and 10.7 g L-1 at pH 3.8. In the case of coculture fermentation, the acetate and PG concentrations were 8.2 and 6.8 g L-1, respectively. Fermentation of lactose and whey powder was conducted at pH 4.25 using a high cell density culture of L. buchneri. The acetate and PG yields were similar for both substrates at ∼0.3 g/g and ∼0.33 g/g respectively. With a starting lactose concentration of 60 g/L, acetate and PG concentrations of 18 g/L and 21 g/L respectively were obtained. The low pH conversion of wastes to value-added products under anoxic conditions provides substantial operating benefits over neutral pH fermentations that require strict anaerobic conditions for effective operation. Moreover, the low product pH at around 4.0 will provide substantial savings in downstream processing costs due to the much higher extraction efficiency of weak- and moderate- base resins for acetic acid compared to acetate ion.

Journal Title: Enzyme and microbial technology

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!