Photo from wikipedia

Abstract Poly(ethylene 2,5-furandicarboxylate) (PEF) is a very promising biobased polymer possessing very high mechanical strength, rigidity and gas barrier performance. But its poor ductility and toughness may limit its applications.… Click to show full abstract

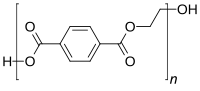

Abstract Poly(ethylene 2,5-furandicarboxylate) (PEF) is a very promising biobased polymer possessing very high mechanical strength, rigidity and gas barrier performance. But its poor ductility and toughness may limit its applications. In this study, PEF-based copolymers with high intrinsic viscosity were successfully synthesized via melt polycondensation of dimethyl 2,5-furandicarboxylate (DMFD) and ethylene glycol in the presence of a copolycarbonate diol (PPeHC diol) as produced from 1,5-pentylene diol (PeDO), 1,6-hexylene diol (HDO) and dimethyl carbonate, and characterized with 1H NMR, 13C NMR, DSC, TGA, tensile, impact and gas barrier testing. The products were “randomnized” as a result of ester-carbonate exchange reaction occurring along melt polycondensation, and therefore became amorphous copolymers possessing composition-dependent physico-mechanical properties which can be tunable from rigid-to-ductile thermoplastics to thermoplastic elastomers. Particularily, the copolymers with φPPeHC of 25 wt% and 30 wt% are thermoplastics possessing greatly improved ductility (elongation at break up to 194%) and CO2 barrier performance higher than poly(ethylene terephthalate) (PET; BIFCO2 3.6–2.8), and retaining high tensile modulus (2.2–1.9 GPa) and yielding strength (69–58 MPa) comparable to the bottle-grade PET. In comparison, the copolymer with φPPeHC of 40 wt% behaves as a high performance thermoplastic elastomer with excellent gas barrier performance as well as high tensile strength (23 MPa).

Journal Title: European Polymer Journal

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!