Photo from wikipedia

Abstract Microencapsulates containing oleoresin of paprika (OP) and blends of soy protein isolate (SPI), maltodextrin (MD) and gum arabic (GA) as wall materials, were analysed to evaluate the components distribution… Click to show full abstract

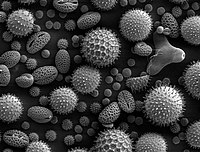

Abstract Microencapsulates containing oleoresin of paprika (OP) and blends of soy protein isolate (SPI), maltodextrin (MD) and gum arabic (GA) as wall materials, were analysed to evaluate the components distribution developed during the encapsulation process. Encapsulation efficiency, glass transition temperature, flowability and physical properties were also assessed. Focused ion beam coupled to scanning electron microscopy (FIB-SEM), confocal laser scanning microscopy (CLSM), X-ray dispersion spectroscopy (EDX) and X-ray photoelectron spectroscopy (XPS) allowed identifying the effects of OP into microcapsules, chemical components distribution, and morphology. In microencapsulated OP, the hollow capsules ranged from 8 to 23% and Tgs (near to 83 °C and 98 °C). The protein concentration on particle surface (18.08%–68.48%) was evaluated by XPS and the surface composition of powders was identified. The best encapsulation efficiency (88.4%) was exhibited by the formulation OP-0.10% SPI-10.45% MD-9.45% GA; the capsules showed the lowest wall thickness and the maximum nitrogen reduction (%) on the particle surface. As a conclusion, OP reduces the presence of hollow capsules and increases the Tg; the soy protein may be responsible for the folds with wide crests on the particle surface, giving a soft and active surface. Although the stability of oleoresin of paprika microencapsulated is associated with the low values of moisture content, aw, and glass transition temperature, the OP on the external surface, could reduce the protective capacity of any wall material.

Journal Title: Food Hydrocolloids

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!