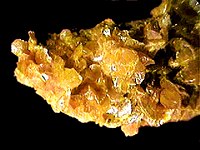

Photo from wikipedia

Abstract Oxidation of arsenic(III) to arsenic(V) is very important in arsenic removal and immobilization operations. Limited studies on arsenic(III) oxidation at pH below 1.5 as is the case of acid… Click to show full abstract

Abstract Oxidation of arsenic(III) to arsenic(V) is very important in arsenic removal and immobilization operations. Limited studies on arsenic(III) oxidation at pH below 1.5 as is the case of acid plant and leaching process effluents have been reported. In this work, the kinetics of As(III) oxidation with SO2/O2 gas mixture at low pH (0.3–1.0) sulfuric acid solutions was investigated in the presence of different iron sources as catalyst: (i) Fe(III); (ii) Fe(II); and (iii) FeOOH residue. In the absence of Fe(III) the initial rate of As(III) oxidation at 90 °C is 0.6 mmol/L·min increasing to 1.1 mmol/L·min with Fe(III)/As(III) molar ratio = 0.1. Higher additions of Fe(III) bring only modest increase in rate. In the presence of Fe(II) the oxidation of As(III) is delayed initially due to competing oxidation of Fe(II) subsequently accelerating with the build-up of Fe(III), which acts as catalyst. Use of FeOOH (industrial goethite residue) provides a cost-effective source of Fe(III) catalytic species while simultaneously acts as neutralizing agent. A complex kinetic behavior is followed. Oxidation is reaction-controlled over the temperature range 25–50 °C shifting to mixed regime control from 70 to 80 °C becoming finally fully mass-transfer controlled at 90 °C. The catalytic role of Fe(III) is rationalized on the basis of a radical chain mechanism.

Journal Title: Hydrometallurgy

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!