Photo from wikipedia

Abstract In order to understand a series of pressure leaf filters located in the downstream line of a bio-based production site, historical process data have been analysed. In general, changing… Click to show full abstract

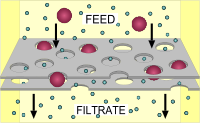

Abstract In order to understand a series of pressure leaf filters located in the downstream line of a bio-based production site, historical process data have been analysed. In general, changing raw materials induce variability into the pressure profiles and thereby cycle durations of the manually reinitialised dead-end filtrations. The absence of a true steady state results in uncertainty about the optimal way of running the filters, and staff members alter the operational specifications frequently. It appears that, in some cases, this propagates disturbances rather than ameliorate them. Statistical analyses are carried out to illustrate the current situation and especially allow quantifying the extent of the uncertainties. Furthermore, significant correlations between process variables are revealed and economically motivated operational objectives are identified. Secondly, working towards on-line predictions of filtration performance, a model is presented. It is based on classical filtration theory and requires only commonly available measurements (pressure, flow, viscosity). The generated predictions are found to be acceptable for many cycles, but in some cases fail due to non-modelled effects, motivating further work.

Journal Title: IFAC-PapersOnLine

Year Published: 2017

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!