Photo from wikipedia

Abstract The next-generation wide bandgap semiconductor single-crystal SiC is extremely stable both mechanically and chemically, which poses problems for micromachining. In this paper, a novel hybrid process combining electrochemical jet… Click to show full abstract

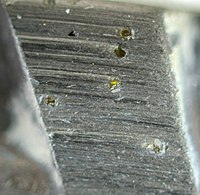

Abstract The next-generation wide bandgap semiconductor single-crystal SiC is extremely stable both mechanically and chemically, which poses problems for micromachining. In this paper, a novel hybrid process combining electrochemical jet anodization and soft abrasive grinding, namely, electrochemical jet-assisted grinding (EJAG), is proposed to enhance both the grinding efficiency and surface integrity of SiC. This process combines characteristics from jet-electrochemical machining (jet-ECM) and grinding into a new micromachining process. In EJAG, the interaction of the jet with the local material efficiently oxidizes the workpiece surface and results in a softened modified layer, which enables the application of soft abrasive grinding to machine SiC with the introduction of little subsurface damage. In this study, details of this hybrid EJAG process are presented, and the process-material interaction is examined experimentally. The material removal mechanism and surface morphology are investigated via anodization/grinding results and scanning electron microscope/atomic force microscope (SEM/AFM) studies. On the basis of a nanoindentation test, the microhardness of SiC decreases by 90% after electrochemical jet anodization (EJA) compared with the unmodified surface. The grinding results show that with the assistance of EJA, both the machining rate and wear resistance of the wheel can be improved. In addition, the surface quality resulted from the proposed EJAG method is close to that from polishing by chemical mechanical polishing (CMP), while the processing time is evidently shorter. By utilizing a cylindrical corundum rod as the grinding wheel, EJAG realized localized machining of microcavities in predefined areas with an extremely smooth surface finish (Sa = 2.18 nm). A three-level and four-factor orthogonal experiment was designed to obtain the optimum conditions. Based on this, a highly efficient material removal rate (MRR) of SiC while maintaining a defect-free surface was demonstrated.

Journal Title: International Journal of Mechanical Sciences

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!