Photo from wikipedia

Abstract Cellulose nanofibers (CNFs) were isolated from banana peel bran via alkaline treatment followed by enzymatic treatment with xylanase. The influence of process conditions such as pH, temperature, and concentrations… Click to show full abstract

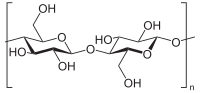

Abstract Cellulose nanofibers (CNFs) were isolated from banana peel bran via alkaline treatment followed by enzymatic treatment with xylanase. The influence of process conditions such as pH, temperature, and concentrations of the enzyme and substrate on the properties of the CNFs was evaluated with a 24−1 fractional factorial design with three central points. Enzyme at 70 U/g of bran, substrate at 15%, pH 6.0, and temperature between 35 and 55 °C favored enzymatic hydrolysis. Transmission electron microscopy (TEM) images confirmed that treatment with xylanase effectively isolated cellulose fibers at the nanometer scale. Fourier transform infrared spectroscopy (FTIR) showed that a fraction of amorphous compounds was removed. X-ray diffraction revealed that the CNFs presented high crystallinity index (66.2%). The CNFs had a diameter of 3.7 nm, their aspect ratio was in the range of long nanofibers, and their suspension was stable (−29.1 mV). These features make the CNFs potentially applicable as reinforcing agents in composites. The results evidenced that enzymatic hydrolysis with xylanase successfully afforded CNFs from banana peel, a residue that constitutes a potential source of biodegradable materials of commercial interest.

Journal Title: Industrial Crops and Products

Year Published: 2017

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!