Photo from wikipedia

Traditional multivariate control charts are unable to determine the specific abnormal variables as detecting process abnormality. To solve this problem, a new model based on optimized random forest (RF) and… Click to show full abstract

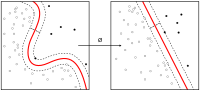

Traditional multivariate control charts are unable to determine the specific abnormal variables as detecting process abnormality. To solve this problem, a new model based on optimized random forest (RF) and multi-feature extraction has been proposed. First, four patterns of process state according to different combinations of abnormal variables are defined. Next, four statistical features and seven shape features are extracted to construct a feature vector, which is used as input of RF in the advanced model. Finally, the particle swarm optimization (PSO) is introduced to optimize the two key parameters of RF. The recognition accuracies of the proposed model are studied through simulation experiments. The experiment results show that the accuracy of this model rises from 91.25% to 98.33% through extracting multi-feature and PSO optimization. The superiority of the proposed model is verified, as evidence by comparing with other algorithms. Thus, we confirm that the proposed model is promising for being applied in real-time process control.

Journal Title: ISA transactions

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!