Photo from wikipedia

Abstract This study aims to reveal how microstructure affect the strength and the plasticity of a metastable β titanium alloy Ti–55531 (Ti–5Al–5Mo–5V–3Cr–1Zr). Lamellar microstructure (LM) and bimodal microstructure (BM) of… Click to show full abstract

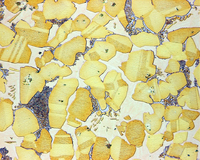

Abstract This study aims to reveal how microstructure affect the strength and the plasticity of a metastable β titanium alloy Ti–55531 (Ti–5Al–5Mo–5V–3Cr–1Zr). Lamellar microstructure (LM) and bimodal microstructure (BM) of Ti–55531 alloy were characterized using transmission electron microscopy, scanning electron microscopy and image analysis software. The deformation mechanisms of LM and BM were systematically investigated by studying dislocation structures of the plastic deformation region (including UDR (uniform deformation region) and NR (necking region)) of tensile specimens. The results indicate that the strength of BM is higher than that of LM. The ductility of LM is equal to or slightly better than that of BM. The deformation of BM is mainly affected by slip and shearing of globular α p (α p , primary α phase). The deformation of LM is primarily controlled by slip, shearing and {101(−) 1}〈112(−) 0〉 twinning of coarsening α s (α s , secondary α phase) lamellae. It seems that twinning can be helpful to improve the ductility of LM to a great extent during deformation. Moreover, the fractographic morphology of LM shows a little more ductile fracture than that of BM.

Journal Title: Journal of Alloys and Compounds

Year Published: 2017

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!