Photo from wikipedia

Abstract A multiple grain size distributed Al-based composite was fabricated through ball milling the amorphous powder mixed with pure Al powder followed by spark plasma sintering. The composite consisted of… Click to show full abstract

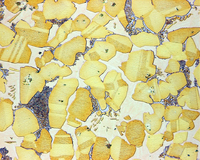

Abstract A multiple grain size distributed Al-based composite was fabricated through ball milling the amorphous powder mixed with pure Al powder followed by spark plasma sintering. The composite consisted of amorphous/nanocrystalline, submicron grain and micron grain, exhibiting outstanding mechanical properties. The superior strengthen effect of the amorphous/nanocrystalline region contributed to the exhibiting specific strength (5.66 × 105 Nm/kg) of the composite. The orderly plastic deformation occurred within FCC-Al micron grain region and submicron grain region during compression. And the progressive deformation restrained the strain localization and unstable propagation of the crack, leading to the plastic deformation (4.3%) of the composite.

Journal Title: Journal of Alloys and Compounds

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!