Photo from wikipedia

Abstract Mg-0.80Ce-0.69Zn-0.03Zr (wt %) alloys were prepared in the state of as-cast, by homogenization treatment at 713 K for 12 h and extruded at 573 K, 623 K, and 673 K with an extrusion ratio… Click to show full abstract

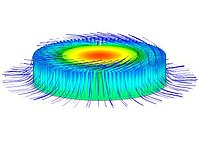

Abstract Mg-0.80Ce-0.69Zn-0.03Zr (wt %) alloys were prepared in the state of as-cast, by homogenization treatment at 713 K for 12 h and extruded at 573 K, 623 K, and 673 K with an extrusion ratio of 10.24: 1. Experimental results reveal that the grains are refined obviously after extrusion. With the increase of extrusion temperature, Zr-containing bar of the extruded alloy is broadened and the texture is weakened, which reduces the anisotropy of thermal conductivity. These phenomena are attributed to the work hardening, recovery, recrystallization, and grain growth, which depend deeply on extrusion temperature. The obvious increase of Ce in Mg matrix according to thermodynamic calculation may act as a major role in the thermal conductivity decreasing of extruded Mg-Ce-Zn-Zr alloy for extrusion temperature increasing from 623 K to 673 K. The recrystallization and grain growth can be driven more effectively at a higher temperature, which should be responsible for the decrease of tensile strength and the improvement of elongation.

Journal Title: Journal of Alloys and Compounds

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!