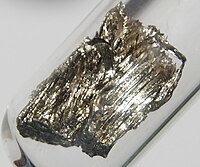

Photo from wikipedia

Abstract Improvements to the properties of Rare Earth Permanent Magnets (REPMs) are needed to advance the capabilities of electric motors and generators, and refinement of the microstructure by the use… Click to show full abstract

Abstract Improvements to the properties of Rare Earth Permanent Magnets (REPMs) are needed to advance the capabilities of electric motors and generators, and refinement of the microstructure by the use of different approaches to processing may be a key means to achieving this. We report here a systematic study into the use of Spark Plasma Sintering to process Sm2(Co, Fe, Cu, Zr)17 permanent magnets. This unfamiliar method for Sm2(Co, Fe, Cu, Zr)17 offers the potential for efficiency savings in reduced processing temperatures and times versus the industry standard vacuum sinter powder metallurgical route, and also offers a refined microstructure of the materials produced. The optimised processing conditions for achieving near-to-theoretical density are reported, and the microstructure and magnetic properties of the materials produced are compared with conventional vacuum sintering. The results provide a basis for further optimisation of these materials.

Journal Title: Journal of Alloys and Compounds

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!