Photo from wikipedia

Abstract The effects of Co on the Cu-Ni-Co-Si alloys' microstructure and mechanical properties were investigated. The Cu-1.5Ni-1.0Co-0.6Si and Cu-1.5Ni-1.5Co-0.6Si alloys with combined aging and 40–80% cold rolling were also investigated.… Click to show full abstract

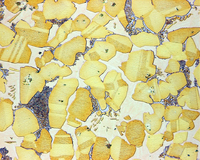

Abstract The effects of Co on the Cu-Ni-Co-Si alloys' microstructure and mechanical properties were investigated. The Cu-1.5Ni-1.0Co-0.6Si and Cu-1.5Ni-1.5Co-0.6Si alloys with combined aging and 40–80% cold rolling were also investigated. The hardness, electrical conductivity, and microstructure were characterized, complemented by X-ray diffraction analysis and transmission electron microscopy. At 450 °C alloys aging, the aging precipitated phases are β-Ni3Si and Co2Si. Specifically, the orthorhombic (Ni, Co)2Si precipitates were found, which have the same crystal structure as the Ni2Si precipitates. The crystal orientation relationship between the matrix and the precipitates is: [112]Cu//[112]β//[012]p, ( 1 1 ¯ 1 ) Cu// ( 1 1 ¯ 1 ) β//(021)p; [001]Cu//[001]β//[001]p, (220)Cu//(110)β//(100)p. With the increasing Co content, the properties of the alloy were degraded. However, Co can promote the growth of the precipitates and accelerate precipitation during the aging process. After aging at 500 °C for 2 h, the hardness and conductivity of the Cu-1.5Ni-1.0Co-0.6Si alloy with 40% deformation were 250 HV and 43% IACS, respectively.

Journal Title: Journal of Alloys and Compounds

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!