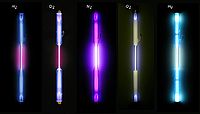

Photo from wikipedia

Abstract Recovering metal values from spent Lithium ion batteries (LIBs) enjoys a great significance in environmental protection and sustainable development of resources. But the application of mixed-type cathode materials in… Click to show full abstract

Abstract Recovering metal values from spent Lithium ion batteries (LIBs) enjoys a great significance in environmental protection and sustainable development of resources. But the application of mixed-type cathode materials in PHEV and EV with high content of manganese brings new challenges for spent LIBs recycling. In this study, a facile approach for directly regenerating Mn-rich cathode material from mixed-type spent cathode materials was developed. The spent cathode materials were firstly tested by X-Ray Diffraction (XRD) and X-ray fluorescence (XRF) and then leached in H2SO4+H2O2 system. The spherical Mn-rich cathode material was directly regenerated from leaching liquor through a facile co-precipitation method followed by solid-phase sintering. The regenerative cathode material was measured by XRD, scanning electron microscope (SEM) equipped with energy dispersive X-ray spectroscopy system (EDXS), inductively coupled plasma atomic emission spectrometry (ICP), laser particle size analyzer and electrochemical tests. According to the results, pure cathode material exhibits a uniform particle size distribution and a layered structure. Furthermore, the regenerative cathode material with high working voltage (>4.5 V) possesses excellent discharge capacity. Cleaner production analysis indicates that whole process can effectively reduce waste residue and water, and helps turn the solid waste into resource. Meanwhile, compared to traditional methods, the proposed process can simplify the recovery process, obtain high value added Mn-rich cathode material and maximize the recovery of manganese in the mixed-type spent cathode materials.

Journal Title: Journal of Cleaner Production

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!