Photo from wikipedia

Abstract A cleaner and atomic economy production of hydroxylamine hydrochloride (NH2OH·HCl) under solvent-free conditions through process intensification is developed to solve the mutual problems of solvent hazard and complicated process… Click to show full abstract

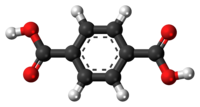

Abstract A cleaner and atomic economy production of hydroxylamine hydrochloride (NH2OH·HCl) under solvent-free conditions through process intensification is developed to solve the mutual problems of solvent hazard and complicated process in traditional methods. The hydrogen peroxide (H2O2), ammonia (NH3) and 2-butanone achieved ammoximation successfully via Ti-MWW in the membrane reaction unit. 2-butanone oxime after dehydration and deamination was hydrolyzed with hydrochloric acid (HCl) in the reaction distillation unit to produce NH2OH·HCl. The catalyst, NH3 and 2-butanone were separated and recycled, respectively. Under optimized conditions, the process showed high the conversion of 2-butanone (97%), selectivity of 2-butanone oxime (100%), yield of NH2OH·HCl (91.6%) and recovery rate of 2-butanone (85.1%). Recycling of materials achieved atomic economy, coupling enhancement of membrane reaction unit, deamination unit and reactive distillation unit achieved high-efficiency continuous process. The whole process ran stably by using Aspen Plus v10 for simulation, the content of H2O2 in the membrane reaction outlet and content of NH3 in the deamination bottom optimized by simulation could meet the requirements of industrialization. The analysis of techno-economic and environment showed that the progress only produced a small amount of waste water which could treat with activated sludge aeration method. The process had low material cost, less environmental impact and high equipment utilization. Therefore, this work can guide manufacturers for the cleaner production of NH2OH·HCl and also provide valuable information for improvement of similar processes and production of similar products.

Journal Title: Journal of Cleaner Production

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!