Photo from wikipedia

Abstract The variations of microstructure and mechanical properties of the joints with different welding heat input were investigated. As the heat input increased, excessive melting of TA15 alloy facilitated the… Click to show full abstract

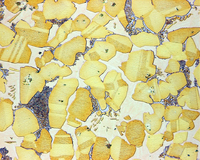

Abstract The variations of microstructure and mechanical properties of the joints with different welding heat input were investigated. As the heat input increased, excessive melting of TA15 alloy facilitated the formation of Ti-Cu compounds at the TA15 interface, increasing the brittleness of the TA15 interface. Moreover, high heat input also caused the HAZ softening by grain coarsening and deteriorated the performance of the joint. However, low heat input was adverse to the complete melting of Cu66V34 alloy and induced the formation of welding pores. It also weakened the strength of the joint. Under optimum welding parameters, (Ti,V) solid solution formed at the titanium interface, replacing Ti-Cu intermetallic compounds (IMCs). Therefore, the joint of sample 2 presented the highest strength (378MPa) and fractured along the HAZ of QCr0.8 alloy due to the HAZ softening resulting from grain coarsening.

Journal Title: Journal of Manufacturing Processes

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!