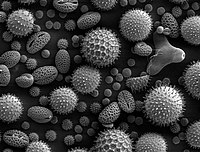

Photo from wikipedia

Abstract An electron beam was used to mainly utilize for polishing, finishing, welding, a lithography process, etc. However, the drilling process does not develop in the country because it is… Click to show full abstract

Abstract An electron beam was used to mainly utilize for polishing, finishing, welding, a lithography process, etc. However, the drilling process does not develop in the country because it is difficult to make high power parts and backing materials. The backing materials are one of the important factors and decided the quality of machined micro holes according to the constituents. This study considers the preparation of vaporized amplification sheets and the analysis of key factors for improving the electron beam processability and efficiency. We evaluated the defoaming process (for removing pores from the sheets), distribution, processability and hole shape (all based on the type of metal powder), and thermal characteristics (based on the type of silicon). Also, we identified process parameters for the optimization of the electron beam machining process.

Journal Title: Journal of Manufacturing Processes

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!