Photo from wikipedia

Abstract Freeform surfaces are widely used in many industries for various purposes, and multi-axis CNC machining is the most adopted method for machining them due to its high accuracy and… Click to show full abstract

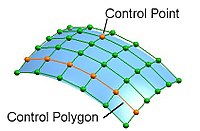

Abstract Freeform surfaces are widely used in many industries for various purposes, and multi-axis CNC machining is the most adopted method for machining them due to its high accuracy and flexibility. The prevailing type of cutter used in machining freeform surfaces is the so-called ball-end type, which is simply a hemisphere and thus has a constant curvature on the cutter surface. Naturally, for a complex surface with a large deviation in curvature, a cutter shape with variable curvature will be more desirable, as we can adaptively choose a portion of smaller curvature on the cutting edge to machine those relatively flat portions on the surface so to enlarge the cutting width and hence reduce the machining time. Towards this objective, in this paper, we present an algorithm which, given an arbitrary freeform surface to machine and a general non-spherical cutter, will generate a five-axis tool path that will strive to match every cutting point on the surface with a locally optimal tool posture (i.e., the contact point on the cutter surface together with the tool orientation) as well as the corresponding optimal feed direction, while both the local gouging-free and global collision-free constraints and the cusp height requirement are all satisfied. The experimental results in both computer simulation and physical machining are also reported, which confirm that, when compared to using a simple ball-end cutter, by using a non-spherical cutter and adaptively adjusting the contacting tool posture and the feed direction, a large improvement in machining efficiency could be achieved, e.g., as much as 60 % achieved in our experiments.

Journal Title: Journal of Manufacturing Systems

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!