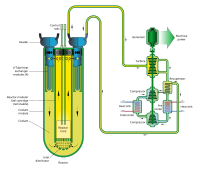

Photo from wikipedia

Abstract An additional function of the permeation barriers is the protective action against corrosion. Although corrosion is not expected to be a major concern for the helium cooled pebble bed… Click to show full abstract

Abstract An additional function of the permeation barriers is the protective action against corrosion. Although corrosion is not expected to be a major concern for the helium cooled pebble bed concept, it is not negligible and the joint action of the working temperature (350oC-550 °C) and the lithium ceramic pebbles produces a corrosion layer in the surface of Eurofer material directly exposed to this environment. Accelerated corrosion tests have been carried out in Eurofer protected by different coatings including Al2O3 prepared by pulsed laser deposition and thermal projection, nano-structured tungsten prepared by DC magnetron sputtering and other commercial coatings based on mixed chromium and aluminum oxinitrides obtained by arc evaporation technique. Tests were performed using a mixture of He/H2O as a purge gas. Two different lithium ceramics pebbles were tested: lithium orthosilicate (K-S) prepared in KIT by the KALOS method and lithium metatitanate obtained by the emulsion method in JAEA (J-T). This paper compares the corrosion layer produced at different temperatures (550 °C and 800 °C) and shows the protection provided by certain coatings under severe conditions of temperature (800 °C) for 730 h. The most promising results have been obtained for aluminum oxide coatings, which stands out this material as the best candidate.

Journal Title: Journal of Nuclear Materials

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!