Photo from wikipedia

Abstract Ti-5Al-5Mo-5V-3Cr (Ti-5553) is a high strength β titanium alloy. It is now commonly used in thick section aerospace components. In general, the thermo-mechanical processing (TMP) of β titanium alloys… Click to show full abstract

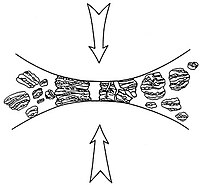

Abstract Ti-5Al-5Mo-5V-3Cr (Ti-5553) is a high strength β titanium alloy. It is now commonly used in thick section aerospace components. In general, the thermo-mechanical processing (TMP) of β titanium alloys done at high temperature to obtain uniformly recrystallized fine grain structure is one of the major challenges. Through this work, a TMP window for Ti-5553 (through systematic variation in % reduction and post deformation annealing temperature) has been developed to obtain fine uniformly recrystallized β grains. Grain size has been quantified on EBSD generated orientation maps, by applying stereological methods, image processing and automated reconstruction. Effects of % deformation and post deformation annealing temperature, as well as that of initial ingot size prior to deformation and the capacity of the forge on the static and dynamic recrystallization behavior, which eventually determine the final grain size distribution, have been illustrated.

Journal Title: Materials Characterization

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!