Photo from wikipedia

Abstract The influence of natural oxide layers at interfaces in diffusion couples is studied. Concentration distributions at (Ni)/NiAl interfaces and the formation of the Ni3Al phase at 650 °C are characterized… Click to show full abstract

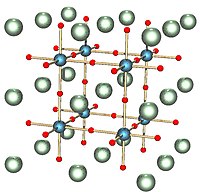

Abstract The influence of natural oxide layers at interfaces in diffusion couples is studied. Concentration distributions at (Ni)/NiAl interfaces and the formation of the Ni3Al phase at 650 °C are characterized using scanning electron microscopy (SEM) and aberration corrected scanning transmission electron microscopy (STEM) with Energy-Dispersive X-ray spectroscopy (EDX) with unprecedented spatial resolution. Employing the common practice of chemical etching with 10 vol% HCl does not remove the oxide layers irrevocably – they are detected at the Kirkendall plane after diffusion annealing of (Ni)/NiAl diffusion couples, if high resolution microscopy is employed. The oxide layer at the Kirkendall plane is of a thickness of ~5 nm, comparable to that of the combined natural oxide layers on the (Ni) and NiAl surfaces. The oxide acts as a diffusion barrier, retarding or locally suppressing growth of Ni3Al into the (Ni) phase. For comparison, oxide-free Kirkendall planes were obtained by subjecting the joining surfaces of (Ni) and NiAl to gentle grinding with low contact pressure in a glove-box in purified Ar atmosphere before assembling the diffusion couple. After diffusion annealing, the Ni3Al layers are distinctly thicker and of a more homogeneous layer thickness as compared to samples with residual oxides. It is shown that evaluating interdiffusion coefficients in oxide-free diffusion couples yields higher values as compared to the conventionally assembled counterparts.

Journal Title: Materials Characterization

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!