Photo from wikipedia

Abstract The superplasticity of a Ti–42.5Al–8Nb–0.2W–0.2B–0.1Y (at.%) alloy with ∼20 vol% metastable β/B2 phase has been examined at temperature range of 850–1050 °C under an initial strain-rate of 10−4 s−1. The results showed… Click to show full abstract

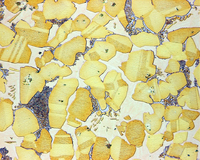

Abstract The superplasticity of a Ti–42.5Al–8Nb–0.2W–0.2B–0.1Y (at.%) alloy with ∼20 vol% metastable β/B2 phase has been examined at temperature range of 850–1050 °C under an initial strain-rate of 10−4 s−1. The results showed that though the proposed alloy has a coarse and bimodal grain structure which was unfavourable for fine-structure superplasticity, impressive elongation was obtained at 1000 °C (∼380%) with a strain-rate sensitivity exponent value of about 0.46. The microstructural characterization showed that remarkable dynamic recrystallization occurred during superplastic tension, and the initial texture-free specimen gradually produced a 〈1 0 0〉 fiber texture whose the main component was cube texture. All these observations seem to be contradictory to the classical theory for fine-structure superplasticity (grain boundary sliding mechanism). Instead, it was suggested that the major deformation mechanism in this alloy was crystallographic slip accompanied by discontinuous dynamic recrystallization.

Journal Title: Materials Letters

Year Published: 2017

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!