Photo from wikipedia

Abstract Remarkable grain refinement of the AZ31 Mg alloy was achieved by low-strain rotary swaging in this study. The grains in the central region of the alloy bars were refined… Click to show full abstract

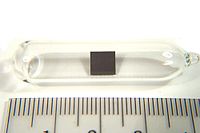

Abstract Remarkable grain refinement of the AZ31 Mg alloy was achieved by low-strain rotary swaging in this study. The grains in the central region of the alloy bars were refined from 548 μm to 95 nm only after three-pass swaging. The formation of nanograins in the central region was mainly attributed to the high strain rate (10–100 s−1) and constantly changing loading directions during swaging. Tension twinning and the formation of dislocation arrays dominated the nanocrystallization process in the central region of the swaged alloy bars. In contrast, only twins were formed but further refinement of the twin lamellae did not occur in the edge region of the swaged alloy bars. Compared with the central region, the edge region was almost loaded toward a single direction (toward the center) during the whole swaging process, which made it impossible for the formation of nanograins.

Journal Title: Materials Letters

Year Published: 2022

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!