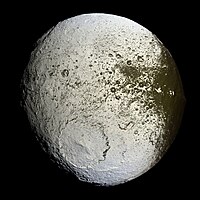

Photo from wikipedia

Abstract This paper describes the first step in the dynamical characterization and numerical simulation of an additive manufactured mechanical component under low velocity impact. The mechanical component, was manufactured by… Click to show full abstract

Abstract This paper describes the first step in the dynamical characterization and numerical simulation of an additive manufactured mechanical component under low velocity impact. The mechanical component, was manufactured by a 3D printer (Renishaw AM 250, Renishaw ©) using the selective laser melting process. Accelerometer was placed in the middle of the component, and an impact was applied, recording both impact force and accelerations. Replication of the experimental setup was replicated using the same component manufactured by subtractive process. For the same loading conditions, comparison was conducted in terms of frequencies, accelerations, and damping curves, illustrating first significant differences between the same structure manufactured via different process. Image processing was also conducted via the use of X-ray, providing interesting non-neglectable difference between the two parts. Discussion concerning this study, limitation and openings are also provided, pointing out specific mechanical features that should be taken into account to understand correctly the behavior of additive manufactured mechanical components.

Journal Title: Mechanics Research Communications

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!