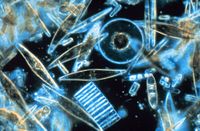

Photo from wikipedia

Abstract Millions of tons of nuts are produced every year in the world (e.g. hazelnut shell, corn stalk, walnut shell) and these vegetal wastes create serious environmental problems. It is… Click to show full abstract

Abstract Millions of tons of nuts are produced every year in the world (e.g. hazelnut shell, corn stalk, walnut shell) and these vegetal wastes create serious environmental problems. It is crucial that these wastes are converted into valuable products using simple and industrially applicable methods. The products obtained are widely used as adsorbents. Some studies utilizing these wastes as raw materials have obtained activated carbon using chemical methods, and employed this activated carbon as an adsorbent. In this study, a product containing carbon nanostructures was synthesized from corn stalk using mechno-thermal method. This product consists of many structures such as carbon nanotubes, carbon fibers, carbon nano-onion and amorphous carbon. We think that this synthesized product is an effective adsorbent. First, corn stalks were carbonized. The carbonized structure was milled for 20 h using a high-energy mill and the particle size was reduced to nano-scale. At the last stage of production, the milled sample was subjected to thermal treatment at 1400 °C. Analyses showed that the product is composed of graphitic carbon structures such as carbon nanotubes, nano-onion, and amorphous carbons. Very thin layers of graphite were also observed in some parts of the product. This study aimed to produce a structure containing carbon nanostructures from corn stalk and achieved this goal. Further research on the use of the product as an adsorbent is in progress.

Journal Title: Journal of Molecular Structure

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!