Photo from wikipedia

Abstract The chemical mechanical polishing (CMP) of Cu/Co/TaN barrier liner stack of the sub-14nm devices was associated with several challenges, one of which was to screen out the desired slurries… Click to show full abstract

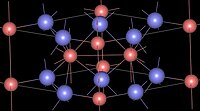

Abstract The chemical mechanical polishing (CMP) of Cu/Co/TaN barrier liner stack of the sub-14nm devices was associated with several challenges, one of which was to screen out the desired slurries formulation. In this paper, the preliminary screening of cobalt (Co) slurries, combined with the orthogonal test method, was reported systematically for the first time. Based on this, the effects of SiO2, H2O2, potassium tartrate, and TT-LYK on the Co removal rates (RRs) were investigated. The corrosion and polishing behavior of the Co in the slurries containing the above additives were investigated by in-situ OCP measurements, potentiodynamic measurements, and polishing experiments. X-ray photoelectron spectroscopy (XPS) measurements were performed to characterize the complexation mechanism between Co and potassium tartrate. It was found that the slurries containing 5 wt% SiO2, 1 wt% H2O2, and 1.2 wt% PT with 900 ppm TT-LYK at pH 9 was a better candidate for Co barrier planarization and effective in minimizing the galvanic corrosion of Co and Cu under Polishing conditions. Finally, Cu/Co/TaN wafers polished with the candidate slurries showed a good RR selectivity. And the atomic force microscopy (AFM) measurements showed excellent post-polish surfaces.

Journal Title: Materials Science in Semiconductor Processing

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!