Photo from wikipedia

Abstract Drilling along the coal seam is an effective way to improve gas recovery. Due to complex coal body structure and natural fractures, there are many difficulties, including a low… Click to show full abstract

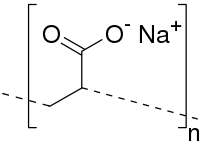

Abstract Drilling along the coal seam is an effective way to improve gas recovery. Due to complex coal body structure and natural fractures, there are many difficulties, including a low abilities of cutting carrying, leakage while crossing the fracture zone and reservoir damage. In this work, a low density degradable polymer drilling fluid system is developed to solve these difficulties to enhance coalbed methane (CBM) production. In the laboratory, the properties of the polymer drilling fluid were evaluated using the coal cuttings suspension experiment, borehole stability simulation test, viscosity attenuation method, laser particle size analysis, polymer removal and core permeability recovery method. The experimental result indicates that the developed drilling fluid has good rheology and filtration, a high yield point and a strong inhibition, thereby meeting conventional drilling requirements and carrying coal cuttings effectively. Under the bio-enzymes, the viscosity of degradable drilling fluid can be initially reduced to 16%. The optimum temperature and pH for the enzyme activity is obtained, and enzymes with small weight fraction of 0.01% can dramatically alter rheological properties of drilling fluid and thereby the high biological activity. After degradation, the particle size in drilling fluid decreases greatly. During immersion test, the polymer film on the surface of the lump coal and thin sections is almost removed by enzyme solution. The reservoir's permeability damage rate may be reduced from 50% to 25% via the functionality of the enzymes, and it is noticeable that the relationships between effective stress and gas permeability treated by the drilling fluid and enzyme still obey the exponential function. Field applications show that the drilling fluid has a good coal fines resistance and compatibility with conventional plugging materials, which ensures the long horizontal footage of 901 m with the short construction period. The later decreased viscosity of the drilling fluid by the enzymes is conducive to reduce the damage to the coal reservoirs.

Journal Title: Journal of Petroleum Science and Engineering

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!