Photo from wikipedia

Abstract The use of colloidal silica in high temperature and low-permeability zones of oil fields for controlling excessive water production is a well-known technique. However, the misplacement of the conventional… Click to show full abstract

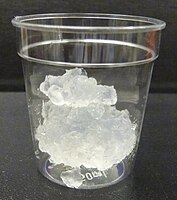

Abstract The use of colloidal silica in high temperature and low-permeability zones of oil fields for controlling excessive water production is a well-known technique. However, the misplacement of the conventional conformance control systems may lead to loss of valuable oil reserves. The Pickering emulsification of silane-modified colloidal silica is a promising solution to this problem. This research demonstrates the use of organophilic micronized phyllosilicate (Cloisite 20) to form an emulsion with silane-modified colloidal silica in a diesel oil phase (invert emulsion) for the first time. The effect of high shear stirring on Cloisite 20 particles and their characteristics were studied to assess their suitability as Pickering stabilizers. Their size, interfacial tension, contact angle, and zeta potential were measured. The developed Pickering-emulsified colloidal silica was characterized using a dilution test, conventional bottle test, vial inversion test, optical and confocal microscopy, and focused-ion-beam scanning electron microscopy. This work provides new insights into the formation and separation of a silane-modified colloidal silica Pickering emulsion. The Cloisite 20 particles were found to be very effective Pickering emulsifier, and the developed emulsion system may have applications for conformance control in high-temperature oil fields with excess water production.

Journal Title: Journal of Petroleum Science and Engineering

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!