Photo from wikipedia

Abstract As a new technology proppant, rod-shaped proppant is receiving more and more attention because it can greatly improve the performance of hydraulic fracturing. With special shape, the rod-shaped proppant… Click to show full abstract

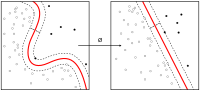

Abstract As a new technology proppant, rod-shaped proppant is receiving more and more attention because it can greatly improve the performance of hydraulic fracturing. With special shape, the rod-shaped proppant is subject to greater flow resistance, resulting in complex migration in fractures. Accurate prediction of the settling velocity of rod proppant in fracture is important for predicting the transport distance and bed height of rod proppant in hydraulic fractures to improve the fracture performance. In this study, high-speed photography and transparent parallel plates were used to simulate and record the settling process of proppant in vertical fractures. A total of 588 effective tests were conducted to reveal the influence of proppant shape, fracturing fluid properties, and the wall effect of fracture on the settling characteristics involving the range of proppant aspect ratio and Reynolds number are 1.5-5.0 and 0.001-172.54, respectively. It was found that the rod proppant settled vertically at the low Reynolds number and horizontally at the high Reynolds number. Therefore, an artificial neural network model of settling orientation with the prediction accuracy of 100% is established as the basis for predicting settlement velocity. The topological structure of the neural network is further extended to establish the prediction model of settling velocity with mean relative error of 1.21%. The relative importance of each input factor to the settling velocity was analyzed by the connection weights algorithm, and the weight and bias of the neural network are provided to realize the application of the model. Finally, the neural network model is evaluated objectively by comparing with the mathematical model. This study is a successful exploration of artificial intelligence in particle migration and will provide guidance for improving the performance of rod proppant in hydraulic fracturing.

Journal Title: Journal of Petroleum Science and Engineering

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!