Photo from wikipedia

Abstract: Gas separation using separation membranes is highly advantageous as they consume less energy and are environmentally friendly and inexpensive. Substituted poly(diarylacetylene)s are potential materials for gas-separation membrane owing to… Click to show full abstract

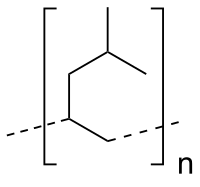

Abstract: Gas separation using separation membranes is highly advantageous as they consume less energy and are environmentally friendly and inexpensive. Substituted poly(diarylacetylene)s are potential materials for gas-separation membrane owing to the excellent permeation performance. Herein, 1-β-naphthyl-2-(4-trimethylsilyl)phenylacetylene (NS) was copolymerized with 1-phenyl-2-(4-tert-butyl)phenylacetylene (TB) and 1-(4-trimethylsilyl)phenyl-2-(4-trimethylsilyl)phenylacetylene (BS) with the TaCl5/n-Bu4Sn catalyst, which afforded high-molecular weight copolymers [poly(NS-TB) and poly(NS-BS)]. The poly(NS-TB) and poly(NS-BS) membranes showed high oxygen permeability (PO2: 3600–6500 barrers). Desilylation of poly(NS-TB) and poly(NS-BS) was carried out using a CF3COOH/hexane mixture to obtain the corresponding desilylated membranes [Dpoly(NS-TB) and Dpoly(NS-BS)]. Desilylation significantly enhanced the gas permeability. The PO2 values of Dpoly(NS-TB) were extremely large (10800–12100 barrers), owing to the large fractional free volume (ca. 0.40). All the membranes maintained a fairly high gas permeability after 150 days of aging. The study results may help in designing better gas separation membranes.

Journal Title: Polymer

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!