Photo from wikipedia

Abstract Flexible but still hard coating materials have been paid attention for applications in flexible electronic devices, as efforts to substitute glasses. However, there have been little approaches to find… Click to show full abstract

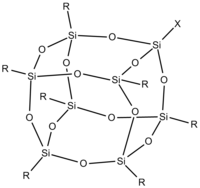

Abstract Flexible but still hard coating materials have been paid attention for applications in flexible electronic devices, as efforts to substitute glasses. However, there have been little approaches to find out control parameters determining their flexibility and hardness. Here, we present reaction-controlled polysilsesquioxane (PSQ) resins with improved flexibility and hardness. In this study, the effects of various reaction conditions on the molecular weight of the PSQ resins are investigated in terms of reaction time, and absence of byproducts, accompanying the analysis of mechanical properties of the corresponding films using nanoindentation. With the reaction-controlled PSQ resins by removing byproducts such as alcohols, the molecular weight could be increased up to 44 % compared to PSQ containing the byproducts. The surface hardness and modulus of hard coating films are also enhanced by 32 % and 13 % compared to that from original PSQ resin, respectively. Finally, we demonstrate folding reliability for 100 k bending cycles at various bending radii of 6 to 1 mm that shows improved warpage property with less irreversible deformation upon the folding test.

Journal Title: Progress in Organic Coatings

Year Published: 2020

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!