Photo from wikipedia

Abstract Online monitoring of the solid phase in industrial processes of sugar crystallization is still a challenge. Laser backscattering is one of the most promising techniques; however, the measured chord… Click to show full abstract

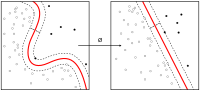

Abstract Online monitoring of the solid phase in industrial processes of sugar crystallization is still a challenge. Laser backscattering is one of the most promising techniques; however, the measured chord length distribution (CLD) does not have a physical meaning of crystal size. This work converted sucrose CLD measured by an online sensor into particle size distribution (PSD) using an artificial neural network (ANN). CLD and suspension concentration of 116 experiments were the input to the ANN and PSD was its output. The trained ANN exhibited a coefficient of variation between experimental and calculated PSD of 0.998. Data of experimental sucrose crystallization was used to validate the model, resulting in a maximum deviation of 0.090 mm in mean size and 6.16% in the coefficient of variation of distribution. This model may be used to improve both industrial processes (process optimization and control) and laboratory studies (kinetics determination).

Journal Title: Powder Technology

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!