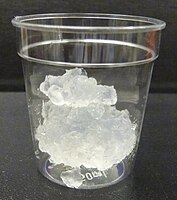

Photo from wikipedia

Abstract Cotton microdust (CMD) was pretreated by a two-stage alkali-acid pretreatment and subsequently subjected to high solids loading enzymatic hydrolysis (HSLEH) and fermentation. The efficiency of the HSLEH of pretreated… Click to show full abstract

Abstract Cotton microdust (CMD) was pretreated by a two-stage alkali-acid pretreatment and subsequently subjected to high solids loading enzymatic hydrolysis (HSLEH) and fermentation. The efficiency of the HSLEH of pretreated CMD was enhanced by optimizing the pretreatment condition using central composite design (CCD) and further improvement of enzymatic hydrolysis was facilitated by the addition of surfactant polyethylene glycol (PEG). The predicted optimized pretreatment conditions for maximum digestibility of cellulose from the regression model were 0.8% (w/v) H2SO4 and 163 °C. The pretreated CMD was efficiently hydrolyzed at high solids loading (35%) to produce high glucose concentration. When PEG was added to the HSLEH mixture with a lower cellulase loading of 22 FPU/g glucan, the concentration of glucose produced was 134 g/L. The fermentation of glucose after the surfactant assisted HSLEH at 35% solids loading produced 66 g/L of ethanol with 96% metabolic yield. The observed levels of reduction of cellulase load and improvement of ethanol production are higher than the reported values for cotton gin wastes. Hence the observed results demonstrated the feasibility of producing high concentration of ethanol from CMD, which would be useful for further improvement and scale-up of the process.

Journal Title: Process Biochemistry

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!