Photo from wikipedia

Abstract Regarding to a die-cutting technology, a shaving process is applied in many industrial fields as a finishing operation to prevent a crack formation and achieve a smooth cut-surface thorough… Click to show full abstract

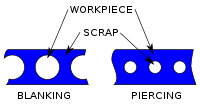

Abstract Regarding to a die-cutting technology, a shaving process is applied in many industrial fields as a finishing operation to prevent a crack formation and achieve a smooth cut-surface thorough material thickness. Based on this advantage, many researches in the past were performed using the experiment and finite element method (FEM) simulation. However, in terms of die-roll formation, the research was rarely carried out. Therefore, in the present research, the process parameters including shearing clearance and shaving allowance relating to the amount of die-roll formation after shaving process is examined. The FEM simulation was used as a tool to investigate the effects of these process parmeters on the amount of die-roll formation and the laboratory experiments were also performed to validate the FEM simulation results. The experimental results agreed well with the FEM simulation results in terms of sheared-surface and shaved-surface characteristics. The results showed that, to achieve a minimum die-roll formation, the small shearing clearance with the large shaving allowance should be recommended.

Journal Title: Procedia Manufacturing

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!