Photo from wikipedia

Abstract Additive manufacturing (AM) has gained increasing popularity in various quality critical applications such as aerospace and healthcare due to its high flexibility in fabricating complex geometries with novel materials.… Click to show full abstract

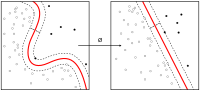

Abstract Additive manufacturing (AM) has gained increasing popularity in various quality critical applications such as aerospace and healthcare due to its high flexibility in fabricating complex geometries with novel materials. However, the relatively poor layer-wise surface quality may lead to compromised property and functionality of AM products. The experimental studies have demonstrated that the AM machine parameters could have significant effects on the resulting surface morphology. Therefore, it is critically needed to analyze the surface morphology in AM and further correlate the morphology features with machine parameters. In practice, there are two major challenges: (1) the surface profiles are usually highly nonlinear; and (2) a large fraction of outliers and missing regions may commonly exist in the measured surface profile. To address these challenges, this paper applies a convolutional autoencoder-based approach to extract informative features from surface profile. With the application of regularization, the autoencoder model is capable of discovering effective low dimensional representations from the high dimensional surface profile data with a large fraction of corruptions. Through supervised machine learning, the correlation between surface morphology and machine parameters can be further quantified. To validate the effectiveness of the proposed method, a case study in laser engineered net shaping (LENS) is conducted to identify the variation of the surfaces fabricated under similar settings of machine parameters. The result shows that the classification accuracy based on the proposed method could achieve 70%, which outperforms benchmark methods. Therefore, the developed convolutional autoencoder-based surface morphology analysis approach has promising potential for surface morphology feature extraction in AM.

Journal Title: Procedia Manufacturing

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!