Photo from wikipedia

Abstract In this document, we report an efficient synthesis of well-defined, soluble, high molecular weight, film-forming aromatic multifunctional homopolymers bearing two distinct functional groups per repeating unit. The polymers were… Click to show full abstract

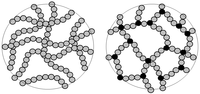

Abstract In this document, we report an efficient synthesis of well-defined, soluble, high molecular weight, film-forming aromatic multifunctional homopolymers bearing two distinct functional groups per repeating unit. The polymers were obtained in nearly quantitative yields by a one-pot, room-temperature, non-stoichiometric superacid-catalyzed step-polymerization of derivatives of pyruvic acid with aromatic hydrocarbons. It was found that thin gold films (2–12 nm) sputtered onto the surface of a multifunctional homopolymer (PTBC) containing carboxy- and bromomethyl- functionalities in every repeating unit undergo spontaneous, solvent-free, room-temperature, quantitative transformation into nanoparticles. For the first time, the key factors affecting film-to-particle transformation were revealed. Internal factors are dependent on the polymer structure, its homogeneity, and the composition of the polymer/metal interface, while external factors include gold-film thickness, temperature and ageing atmosphere. By varying the functional-group combinations and aromatic fragments, a set of multifunctional homopolymers has been synthesized and it was found that the presence in the homopolymer of a repeating unit of two phenylene rings and two functional groups – bromomethyl and carbonyl – attached to the same carbon backbone atom (forming a so-called “Reactive site”) is critically important for film-particle transformation. The process is accelerated with increasing temperature, proceeds in ambient air, and is halted in a vacuum. The average grain size of the nanoparticles increased from 3 to 18 nm over a week at room temperature and from 5 to 27 nm over the same period at 40 °C. The size and shape of the nanoparticles are modulated by controlling the thickness of the gold film, the temperature and the ambient atmosphere. The transformation represents a very simple, one-step, environmentally-friendly process that is not dependent on any other chemical reagents, requires no previous temperature or high-energy processing, and can easily be scaled up to fabricate high-purity, fully accessible polymer-(film- or nanofiber-) supported gold nanoparticles of long-term stability.

Journal Title: Reactive and Functional Polymers

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!