Photo from wikipedia

Abstract Fibrous nonwoven filters are widely used in various air filtration applications. Coarse filters are typically used to protect and extend the lifetime of high-efficiency filters. However, unlike high-efficiency filters,… Click to show full abstract

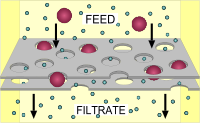

Abstract Fibrous nonwoven filters are widely used in various air filtration applications. Coarse filters are typically used to protect and extend the lifetime of high-efficiency filters. However, unlike high-efficiency filters, limited work had been carried out to study the evolution of filtration properties and filter structures during the clogging process of coarse fibrous filters due to the lack of non-invasive and non-destructive structural characterization techniques. In this study, a coarse nonwoven filter media with a 94.52% mean porosity value was fabricated. The filtration properties of the studied coarse filter, including pressure drop and filtration efficiency, were found to increase along with the particle loading. The X-ray micro-computed tomography (XMCT) was used to non-invasively characterize the 3D structures of clean and particle-loaded fibrous nonwoven coarse filters at different clogging stages. Although the surface area scanned by XMCT (research of interest, 600*600 µm2) was a tiny spot on the whole filter media, this surface area exhibited good representativeness of the average structural properties of the whole filter media, e.g., porosity in this study. Depth profiles of local porosity and particle solidity across the full thickness of filter XMCT image indicated that at the beginning of particle loading stages, particles were captured and trapped by the top part of filter thickness, which was corresponded to the reported clogging process of high-efficiency filters. Then particles could be found across the full filter thickness. However, during the transitioning from the depth filtration stage to the surface filtration stage, clogging with high particle solidity was found in the bottom part of filter thickness. As more particles were loaded, clogging was found in both the middle and bottom parts. After that, the top part would be clogged, and the surface cake would start forming thereafter. This is the first report of the clogging process of the fibrous nonwoven coarse filter. Pore diameter distribution derived from the pore skeleton network via skeletonization of the 3D particle-loaded filter structures also described the same structure evolution during dust loading.

Journal Title: Separation and Purification Technology

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!