Photo from wikipedia

Abstract When drilling the carbon fiber reinforced plastics (CFRP), the tool shape and surface coating both play important roles in the cutting performance, which are complex and comprehensive, and should… Click to show full abstract

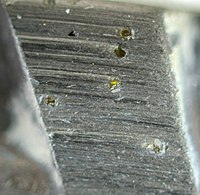

Abstract When drilling the carbon fiber reinforced plastics (CFRP), the tool shape and surface coating both play important roles in the cutting performance, which are complex and comprehensive, and should be systematically studied. In this research, WC-6wt.%Co drills in typical shapes are prepared, on which high-performance composite diamond films are deposited by the hot filament chemical vapor deposition (HFCVD) method. It is firstly proved by drilling tests that the tool shape always acts as a determining factor that significantly influences the drilling force and machining quality, for either the uncoated or diamond coated drills. The shorter chisel edge, smaller actual point angle and the proper double point angles are all factors in their favor. By contrast, as-deposited diamond films can slightly reduce the drilling force, while sometimes it even deteriorates the hole quality, due to the edge roundness caused by the alkali-acid pretreatment and the film growth. However, the diamond films play critical roles in improving the wear resistance, elongating the lifetime and guaranteeing the stability of the machining quality in the long-duration drilling process. In addition, the tool lifetime is also closely associated with the tool shape, attributed to the different thrust forces, consequently the lifetime of the diamond coated standard twist drill is much shorter than those of all other coated ones.

Journal Title: Surface and Coatings Technology

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!