Photo from wikipedia

Polyhydroxyalkanoates (PHAs) are a diverse family of sustainable bioplastics synthesized by various bacteria, but their high production cost and unstable material properties make them challenging to use in commercial applications.… Click to show full abstract

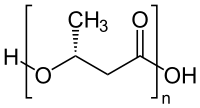

Polyhydroxyalkanoates (PHAs) are a diverse family of sustainable bioplastics synthesized by various bacteria, but their high production cost and unstable material properties make them challenging to use in commercial applications. Current industrial biotechnology (CIB) employs conventional microbial chassis, leading to high production costs. However, next-generation industrial biotechnology (NGIB) approaches, based on fast-growing and contamination-resistant extremophilic Halomonas spp., allow stable continuous processing and thus economical production of PHAs with stable properties. Halomonas spp. designed and constructed using synthetic biology not only produce low-cost intracellular PHAs but also secrete extracellular soluble products for improved process economics. Next-generation industrial biotechnology is expected to reduce the bioproduction cost and process complexity, leading to successful commercial production of PHAs.

Journal Title: Trends in biotechnology

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!