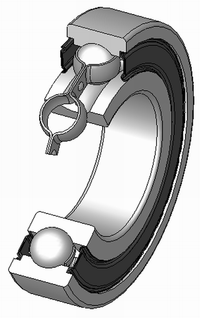

Photo from wikipedia

Abstract In high speed roller bearings, the drag force due to the oil-air mixture present in the bearing cavity – that is acting against the roller movement – is usually… Click to show full abstract

Abstract In high speed roller bearings, the drag force due to the oil-air mixture present in the bearing cavity – that is acting against the roller movement – is usually computed with a two-dimensional model of flow around a cylinder of infinite length. However rollers are of finite length, and the flow is perturbed by the two free ends, the surrounding rings, the cage and other rolling elements. In this article, the Computational Fluid Dynamics (CFD) method is employed to analyze first the flow around one finite-length circular cylinder with two free ends in an open space. Then the model is changed to one finite cylinder and then several in-line circular cylinders sandwiched by two flat walls, which represents a simplified approach. The results indicate that both the flow pattern around the cylinder and its drag coefficient are modified in comparison with the two-dimensional model. Finally a relationship between the drag coefficient and the Reynolds number suitable for circular cylinder in roller bearings is proposed.

Journal Title: Tribology International

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!