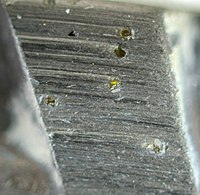

Photo from wikipedia

Abstract This study presents a numerical model of the grinding force during rail grinding that considers the influence of the swing angle of the grinding stone on the position of… Click to show full abstract

Abstract This study presents a numerical model of the grinding force during rail grinding that considers the influence of the swing angle of the grinding stone on the position of the grinding area. The numerical model of movement process and material removal of single abrasive grain at different swing angles are established. The surface characteristics of the grinding stones, such as protrusion heights and density of grains, are measured to establish the model of grinding force in the whole grinding area. The results indicate that the grinding forces increase with the grinding pressure and forward speed. In contrast, the grinding forces decrease with the increasing rotational speed and grinding stone granularity.

Journal Title: Tribology International

Year Published: 2019

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!