Photo from wikipedia

There is increasing demand in the electronics recycling industry for an effective method to separate polyvinyl chloride (PVC) and Cu from thin electric cable waste. Herein, a novel separation technique… Click to show full abstract

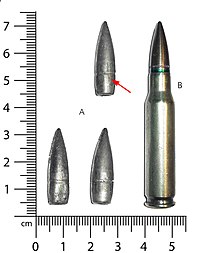

There is increasing demand in the electronics recycling industry for an effective method to separate polyvinyl chloride (PVC) and Cu from thin electric cable waste. Herein, a novel separation technique involving PVC embrittlement via plasticizer extraction and crushing by ball milling is proposed. The method was developed by varying the size, quantity, and hardness of the cables, as well as the size and quantity of the milling balls, to determine a combination that resulted in complete separation of PVC and high-purity Cu (>99.9%) from thin electric cables. The experimental crushing behavior was demonstrated via a sphere-to-cylinder discrete element model combined with a statistical approach. The mechanism of PVC crushing generated cracks from the edge to the center of the cable via ball impacts that were strong enough to overcome the elastic repulsion force of the PVC. The resulting method was found to be effective at separating PVC and high-purity Cu (>99.9%) from de-plasticized thin electric cables with diameters of 1.5-2.7 mm.

Journal Title: Waste management

Year Published: 2018

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!