Photo from wikipedia

Abstract Titanium sheets find their wide application in aerospace industry. Rolling process is commonly used for making these sheets. Inducing large amount of strain in high strength materials with HCP… Click to show full abstract

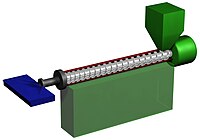

Abstract Titanium sheets find their wide application in aerospace industry. Rolling process is commonly used for making these sheets. Inducing large amount of strain in high strength materials with HCP structure such as Magnesium and Titanium alloys makes rolling a multistage process. Moreover, controlling crystallographic texture in multistage deformation processes is also very critical. To overcome these limitations, in present research attempt large strain extrusion machining (LSEM) process is used to produce laminates from CP titanium sheets with controlled microstructure in a single continuous operation. These CP Ti laminates are produced at different strain rate. Microstructural analysis and hardness measurement of fabricated laminates are carried out using scanning electron microscopy and Vickers microhardness tester respectively. Roughness tester is used for roughness measurement. X-Ray diffraction is used for deformation analysis of the laminates. Sliding wear tests on produced laminates are performed using tribometer. Hardness measurement revealed a ~25–52% increase in hardness value in fabricated laminates as compared to bulk material. This increase in hardness may be attributed to grain refinement resulted from high deformation induced by LSEM process. The surface roughness of fabricated laminates decreased with increase in strain rate. Wear rate analysis of the samples have shown improved wear performance of laminates fabricated by the process in comparison to bulk material. Wear rate is observed to be lower in direction perpendicular to laminate formation direction.

Journal Title: Wear

Year Published: 2021

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!