Photo from wikipedia

Al alloys possess many favorable characteristics which make them useful in a wide variety of application. Particularly, the Al2024 alloys are extensively used as structural materials in commercial airplanes owing… Click to show full abstract

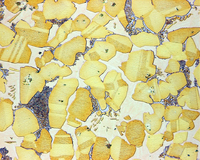

Al alloys possess many favorable characteristics which make them useful in a wide variety of application. Particularly, the Al2024 alloys are extensively used as structural materials in commercial airplanes owing to their good balance of properties including high specific strength, formability and corrosion resistance [1, 2]. These properties are mainly important in the aerospace industry. These alloys are currently used in high volume manufacturing in the aerospace e.g. aircraft wing and fuselage structures are made of T3 and T4 Al2024 alloy sheet [1-2]. By another hand, the mechanical properties of this alloy can be influenced by artificial aging and by plastic deformation, such as equal channel angular pressing, high pressure torsion and cold rolling. However, only few of thermomechanical treatments have been practically applied to Al alloys, like heat treatment T8 of Al2024 and T9 of Al2A12 alloys [4], in which the applied deformation is relatively small. The reason is to avoid the introduction of the non-uniform distribution of dislocation cell structures which may act as nucleation sites of heterogeneous precipitation [4]. Although, it should be mentioned that a significant increase of the strength was achieved by relatively large cold deformation after solution treatment in others studies [5]. The aim of this work is evaluate the effect of plastic deformation on microstructure and hardening of the 2024 Al alloy (Al2024) modified with 0.25 wt. % of Mg additions (Al2024-0.25 Mg).

Journal Title: Microscopy and Microanalysis

Year Published: 2017

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!