Photo from wikipedia

In this study, a wet scrubber coupled with a persulfate-based advanced oxidation process [carbocatalysts/peroxymonosulfate (PMS)] was demonstrated to efficiently remove gaseous volatile organic compounds (VOCs). The removal efficiency of a… Click to show full abstract

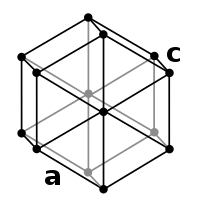

In this study, a wet scrubber coupled with a persulfate-based advanced oxidation process [carbocatalysts/peroxymonosulfate (PMS)] was demonstrated to efficiently remove gaseous volatile organic compounds (VOCs). The removal efficiency of a representative VOC, styrene, was stable at above 98%, and an average mineralization rate was achieved at 76% during 2 h. The removal efficiency of the carbocatalysts/PMS wet scrubber for styrene was much higher than that of pure water, carbocatalysts/water, or PMS/water systems. Quenching experiments, electron spin resonance spectroscopy, in-situ Raman spectroscopy and density functional theory (DFT) calculations indicated that singlet oxygen (1O2) and oxidative complexes are the main reactive oxygen species and that both contributed to styrene removal. In particular, carbonyl groups (C═O) in the carbocatalyst were found to be the active sites for activating PMS during styrene oxidation. The role of 1O2 was discovered to be benzene ring breaking and a possible non-radical oxidation pathway of styrene was proposed based on time-of-flight mass spectroscopy which was further verified by DFT calculations. In particular, the electron transfer process of multi world carbon nanotubes-PMS* in styrene oxidation was further studied in-depth by experiments and DFT calculations. The unstable vinyl on styrene was simultaneously degraded by the oxidative complexes and 1O2 into benzene, and finally oxidized by 1O2 into H2O and CO2. This study provides an effective method for VOC removal and clearly illustrates the complete degradation mechanism of styrene in a nonradical PMS-based process by a wet scrubber.

Journal Title: Environmental science & technology

Year Published: 2022

Link to full text (if available)

Share on Social Media: Sign Up to like & get

recommendations!